RC01-E EV Battery Electrolyte and Air Leak Tester (High & Low Pressure)

RC01‑E Electrolyte & Air Leak Tester

The RC01‑E offers comprehensive battery pack inspection with three key functions: electrolyte leakage testing, low‑pressure leak testing, and high‑pressure leak testing. It enables non‑destructive detection of electrolyte vapor inside sealed battery packs by extracting internal gas with a vacuum pump and analyzing the electrolyte concentration in parts per million (ppm) before opening. The device is designed for electric vehicle battery housings and battery cooling systems and is especially suited for aftersales service and workshop applications.

RC01-E – Battery Electrolyte & Air Leak Tester

For HV EV Battery Aftersales Service, Repair Workshops and Battery Pack Production

Application and Function – Electrolyte Leakage Detection

The RC01-E Battery Electrolyte Leak Tester is connected to the fully sealed high-voltage battery. Using its integrated vacuum pump, the device extracts air from inside the battery housing and analyzes it for electrolyte vapor concentration (ppm). The permissible threshold can be configured according to OEM specifications. The result is displayed clearly as PASS or FAIL:

PASS – No electrolyte vapors detected

The battery can be safely opened and repaired under standard workshop conditions.FAIL – Electrolyte vapors detected

The battery must only be opened in a controlled safety environment, as leaked electrolyte vapors can pose health hazards and indicate internal cell or module damage.

The test duration is typically 10–30 seconds, depending on the battery’s internal air volume.

Quality Assurance After Repair or Service

After completing repair work, the RC01-E can be used to validate the repair by performing a post-repair electrolyte leak test. In addition, the device provides two pressure-based leak testing functions:

Low-Pressure Leak Test

Ensures the battery enclosure is airtight by applying a slight under- or over-pressure to detect even very small leaks.High-Pressure Leak Test

Verifies the cooling system integrity (cooling plates, coolant channels, pipe connections) under elevated pressure to ensure proper function of the thermal management system.

All test results are automatically stored in an integrated database, enabling:

Full traceability of all diagnostic and repair steps

Quality documentation for customers

Compliance with OEM and audit requirements

This ensures that every serviced battery meets defined safety, reliability, and performance standards before returning to operation.

Application in Battery Production and Pack Assembly

The RC01-E is also designed for quality assurance in battery manufacturing. During laser welding of battery cells and contact plates, invisible micro-cracks may occur in the cell casing. If a weld seam overheats or burns through, electrolyte may escape — resulting in:

Health risks for production personnel

Reduced cell performance or complete cell failure

Increased rework and production waste

To detect such defects early, the battery module or pack can be placed into an airtight test chamber (standard chamber volume approx. 10 L) and connected to the RC01-E. The device generates a vacuum and analyzes the extracted air for traces of electrolyte vapors — allowing rapid and reliable leak detection before the pack moves to the next production stage or is shipped.

Larger chambers or customized process settings can be configured upon request.

Designed for Both Aftersales Service & Industrial Manufacturing

| Application Area | Purpose | Benefits |

|---|---|---|

| HV EV Battery Aftersales & Repair Workshops | Safe evaluation of sealed batteries before opening; verification after repair | Increased technician safety, reduced risk, validated repair quality |

| Battery Manufacturing & Pack Assembly | Inline or end-of-line leak and electrolyte detection | Reduced rework, improved production yield, reliable quality control |

The RC01-E is therefore a dual-purpose solution:

✔ Battery Electrolyte Tester for EV repair and workshop safety

✔ HV EV Battery Air Leak Tester for production and assembly quality assurance

Electrolyte detecting

- Electrolyte Testing:Yes

Technical Details

- Low pressure range:0~10kPa

- High pressure range:10~500kPa

- Testing resolution:0.1Pa

- Pressure sensor accuracy:+/-0.02%FS+0.05%FS

- Pressure repetition accuracy:0.1%FS

- Pressure regulating mode:automatic pressure regulation

- Air Supply:0.4~0.8MPa (clean and dy air)

- Data Storage:16GB

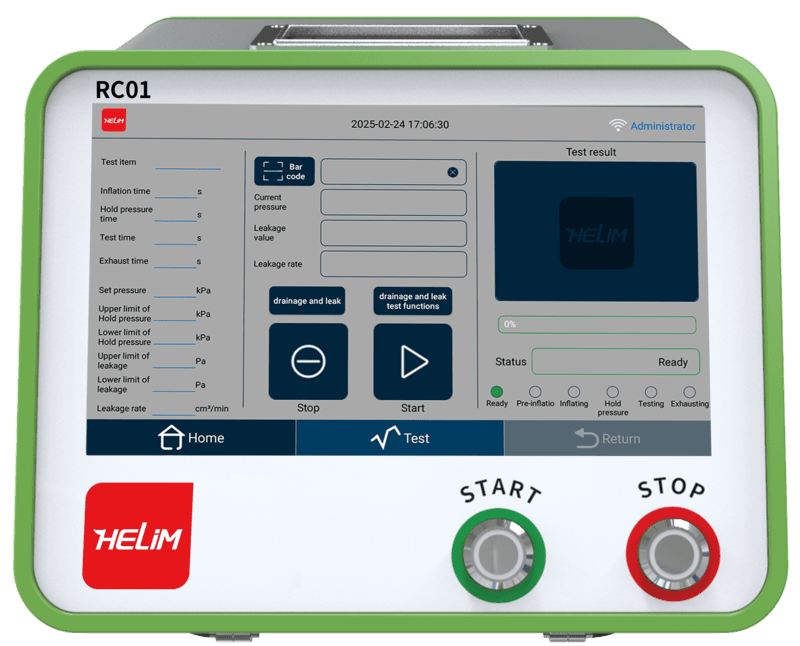

- Display:10.1" multi-point color touch screen

- System:Android 4.4.2

- Core Module:CPU:1.4GHz / RAM:1GB

- Number of programs:1000 Groups

- Operating temperature:0~50°C

- Power supply:AC110~240V 50Hz

- Dimensions:280x374x232 mm

- Net Weight:9.2kg